Crematory Operators! Just because you always did it that way doesn't mean it's not the best way to do it!

No Peeking

There is no reason to open the door of the cremator while it is running. If you aren’t good at estimating the total time for a case and always feel like the case is complete before the timer finishes, shorten your time on the next case. You can always add time if you need to. Most modern equipment is designed to regulate the air to perfection. Opening the door could add more air at the wrong time and create a reaction where the rate of combustion becomes too fast for the system to handle. Repositioning the body mid-way through the cremation is also not a good reason to open the door. It is both undignified for the deceased and unnecessary with modern equipment. If parts of the bottom of the casket are not complete at the end of cremation, you can reposition the cremated remains at that time. This is far different than repositioning a body mid-way through the process, and far more dignified.

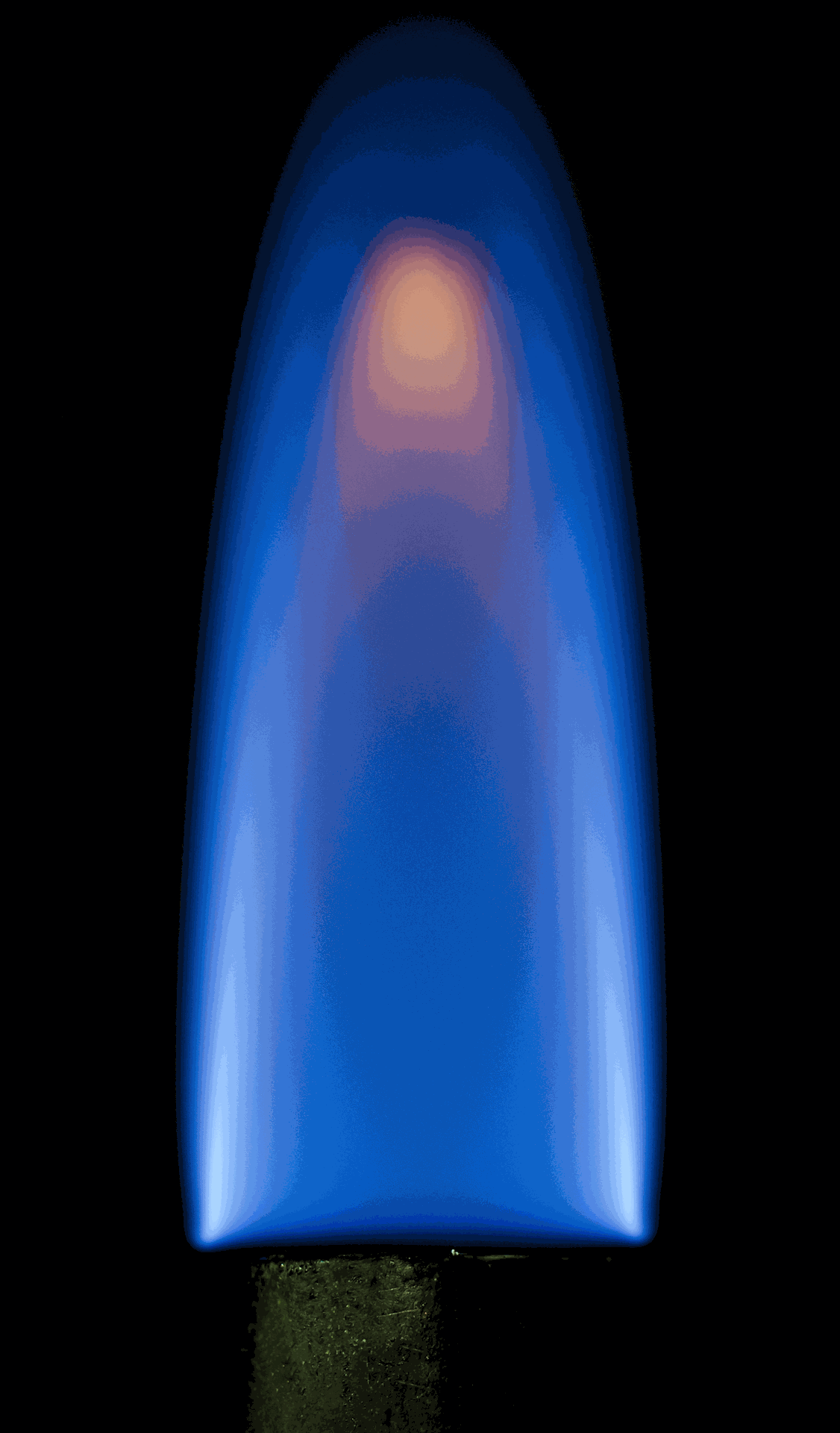

Preheat to 450°

The reduction of a dead human body by combustion involves fire. With fire comes heat, which is necessary for an efficient combustion. To assure that the secondary chamber has the heat necessary, it must be preheated before anything even gets loaded in to the main chamber.

Modern equipment is designed to prevent an operator from starting the main combustion burner until the secondary chamber temperature is hot enough. In some areas this pre- heat temperature is regulated by law. It is important that this safety feature is not hacked and bypassed.

ELVIS HAS LEFT THE BUILDING

One of the most common bad habits born out of necessity is starting a cremation and then leaving to do something else. Unfortunately, we all wear many hats and other duties need to be performed in the course of our day. However, most issues present themselves during the first hour or so of

a cremation, so it is necessary for the operator to monitor the progress of the cremation and make any manual adjustments to assure a safe and controlled cremation cycle. There can be surprises even with the most sophisticated of control systems during a standard everyday case. It’s always best to expect the unexpected!

As an equipment operator becomes more familiar with their unit, they may also be better able to anticipate potential problems with materials entering the unit, before the cremation becomes out of control. This lessens the obligation to monitor the cremation so closely. But, especially for new operators, it is always a wise choice to err on the side of caution.

Hoarders

Over the course of a cremator’s life many of its parts will be replaced. Thermocouples (temperature probes) will go out, flame rods or pressure valves will malfunction. This is all normal and expected as nothing lasts forever. It is important to properly dispose of all parts that are no longer functional. It will only compound your problems if you complete a repair with a faulty part mistaken for a good one.

All Units are Not Created Equal

As the cremators of the 70s, 80s, and even 90s are being replaced with modern fuel efficient systems, long time operators are having a hard time adjusting to the newer more automatic units. Check your ego at the door and realize although these units may look like the unit you operated for 30 years, it does not operate like it.

Listen to the technician during the commissioning and training for the new unit. Discover how the new unit handles the variety of body sizes and casket compositions differently than the old unit. Learn the new tips and tricks to combat a “run away” cremation. Control systems are far more sophisticated now; the way they control air and its distribution throughout the system is a game changer. Do not think that because you have operated a cremator for 30 years that you will be an expert at operating new equipment.

CHILL OUT

Most units are designed to cool down to approximately 400ºF before being swept out. This is for many reasons, primarily operator safety. The refractory lining in these units is also designed to expand and contract as the system heats and cools. This helps with their longevity.

Waiting until the unit is cool to do the next cremation also helps prevent premature ignition of the case which can be extremely dangerous. It can also help to prevent a “run away” cremation; the cremation is better controlled with less heat at the start, and the likelihood of overheating is decreased.

Some units will cool down quickly whereas others may take hours. Some units are even designed to run continuously. With these units, an automatic loading device is needed to assure the safety of the operator. The clean-out procedures are also designed to keep the operator from exposure to the intense heat.

Regardless of the unit, operators must always wear protective gear to safeguard against harm from the heat.

CLEANLINESS IS NEXT TO...

For areas that contain dead bodies it is surprising that there are a significant number of crematories that are not clean and tidy places. According to the US Environmental Protection Agency (EPA) human remains are potentially infectious before, prior and even after embalming. I’ve seen facilities with bodies piled up everywhere, dirty floors with fluids, dirt and grease, surfaces coated in dust and grime. Even cremated remains boxes sitting on tables and shelves in no apparent order with no visible means of identification.

As cremation becomes more popular so will the public’s desire to visit cremation facilities before deciding on which firm to use. Open and clean facilities with an engaged and knowledgeable staff are going to win the race every time. Dust in a crematory, to a layperson, looks like someone’s ashes.

No one wants to think of their deceased love one sitting in a corner under two more dead bodies waiting for their turn, and no one wants to go home from work with an infectious disease.

Clean and straighten your place daily. Clean up any spills with a sanitary solution of 1:10 bleach and water. Sweep the floors and mop as appropriate weekly. Dust o all surfaces on a regular basis. Treat your crematory like you treat your funeral home. It should be a showplace just as nice as any other room in your business.

OPEN PANDORA’S BOX

The first step to assure your safety and reduce the volume of pollutants released into the atmosphere is to examine the materials included with the remains to be cremated. Often friends and loved ones will place objects into the casket as

a token of remembrance or as a personal gesture. Items like stu ed animals, picture frames, bullets, etc., are not meant to be cremated. They could damage the unit, cause unnecessary toxic pollution, or even compromise the safety of the operator.

There have been many instances of bullets placed into the casket of an avid hunter by his buddies. You can imagine the consequences of cremating such items. Even something as insignificant as a soda can could be dangerous for those around the unit. A can under pressure will explode when heated potentially causing damage to the inside of the unit and anxiety for the operator. At the very least he or she will need to return home for a change of underwear after that. Cremators are not designed to cremate plastics. Always remove plastic items in the casket and remove any plastic hardware attached to the outside. These plastics, including those used to make stu ed animals, will melt and vaporize, releasing toxic chemicals into the atmosphere. Plastics containing chlorine (think PVC) are especially dangerous, as the chlorine will bond with hydrogen and form deadly hydrogen chloride gas. What doesn’t vaporize will adhere to and damage the floor of the unit.

Despite all the safety and environmental hazards associated with cremating such items, in some parts of North America the operator is not legally allowed to open the casket prior to cremation due to regulatory laws. In these areas it is important to let your lawmakers know the potential consequences of this restriction.

HIT THE BOOKS

Most funeral professionals have attended continuing education sessions to enhance their knowledge and abilities on subjects such as pre-need sales, casket sales or embalming/ restorative techniques, but have never attended a crematory operations educational session. Many crematory operators performing cremations every day have no more training than the 45 minutes their manufacturer spent with them during the equipment installation. With the continued rise of cremation rates across North America this seems unreasonable. Anyone that touches cremation in any way, from the business owner to the funeral director/arranger, to the equipment operator to the person answering the phone should learn as much as possible to become the best cremation professional possible.

Fortunately professional associations offer a multitude of options for cremation education and certification and can be counted on to provide nothing but the best information.

Any operator certification class you attend should include a significant portion of curriculum from a manufacturer.

The way this equipment is designed, engineered and built is essential to understanding how to operate it.

DAMN IT JIM…..I’M A CREMATIONIST, NOT A TRAINED MONKEY

The days of cremations being performed in a back lot building out of sight and out of mind are long behind us as a profession. Unfortunately, the public still has this

perception. Only we, as cremation professionals, can change the mindset of the public through education, outreach and most importantly by being a shining example of cremation excellence. It may sound silly, but it really is essential for our further relevance as more than just people that burn and return dead bodies in a plastic box.

Someone loved that person in the box and the cremationist cannot lose sight of this. I’ve seen facilities with bodies in cardboard boxes stacked 4 and 5 high waiting in the summer heat for their turn in the cremator. When confronted with questions about the dignity of the deceased I was told, “They are only going to be burned up shortly, what does it even matter?” It matters to those individual’s families and loved ones! I even saw a cremationist eating his lunch on the top of an air tray waiting to be loaded into the cremator. Always take the time to think about what you would do if the spouse of the person you are handling were in the room with you.

This way of thinkinhg may reveal that some habits that were okay in the past, but not appropriate for a modern, clean, safe and welcoming operation.

10 Bad Habits Crematory Operators Need to Break Now!